FAQ's

Welcome to Aceites Artajo's Frequently Asked Questions.

The olive is composed of vegetable water, solids and oil. Extra virgin olive oil or ‘EVOO’ is the ‘oily juice’ of the olive obtained by physical means and which also has an acidity of less than 0.8? and has no organoleptic defects. It is also the only vegetable fat suitable for human consumption without undergoing deodorising and refining processes (chemical process).

First cold pressing: Extra virgin or virgin olive oils obtained at less than 27 °C by first mechanical pressing of the olive paste using a traditional extraction system with hydraulic presses.

Cold extraction: extra virgin or virgin olive oils obtained at less than 27 °C by filtering or centrifuging the olive paste. At Artajo, cold extraction is carried out using stainless steel machinery to maintain cleanliness and freshness, shortening times as much as possible to avoid oxidation of the olives and the paste during the process. On the label of our products, in addition to ‘cold extraction’, a more important parameter for determining quality appears, which is acidity. The lower the acidity of an extra virgin olive oil, the lower the percentage of free oleic acid and therefore the bonds between the oleic acid and the glycerin have not been broken or ‘spoiled’ during the process.

Once the oil has been extracted at the mill by mechanical means, a sample per deposit must be sent to a laboratory to determine the category to which the oil belongs. Analytical parameters such as acidity, peroxides and waxes are obtained in the laboratory to determine whether the oil has been extracted correctly and has not been subsequently altered. In addition to an analytical test, the sample must also pass through a tasting panel to measure parameters such as fruitiness, bitterness, pungency and organoleptic defects (such as rancidity, rancidity, vinegary, mould, etc.).

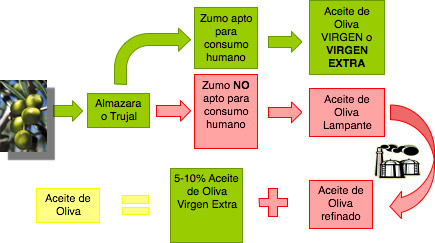

According to the results obtained, the oil obtained from the mill is categorised as:

- Extra virgin olive oil: The free acidity expressed as oleic acid must be a maximum of 0.8 g per 100 g (0.8º). Fruitiness must be detectable on the panel and there must be no organoleptic defects.

- Virgin olive oil: The free acidity expressed as oleic acid is a maximum of 2.0 g per 100 g (2º). The panel must detect the fruitiness and it already has some kind of defect, up to a score of 3.5 out of 10.

- Lampante virgin olive oil: The free acidity expressed as oleic acid is higher than 2 g per 100 g (>2º) or the panel detects defects above a score of 6.5 out of 10. It is not suitable for human consumption. It is intended for refining for human consumption or technical uses.

This last category of oil is not marketed in packaging, as this is not permitted. It must first go through an industrial refining process, whereby it is subjected to different chemical processes, whereby its acidity is neutralised and corrected and defective aromas and flavours are eliminated.

Once refined, it is marketed mixed with a small percentage of virgin olive oils and is known as ‘olive oil’. The one with less virgin oil is commonly known as ‘0.4º’ or ‘mild’ and the one with a slightly higher percentage is known as ‘1º’ or ‘intense’. This type of oil is no longer the same product as extra virgin olive oil and its organoleptic and health properties are no longer the same.

The acidity of extra virgin olive oil is not related to the characteristic sour taste of citric and acetic acids, for example, as it is simply a chemical parameter that expresses the amount of free fatty acids contained in the oil. A low quantity of these will always indicate that the extra virgin olive oil has been produced from healthy olives and that it has been treated in optimum conditions during the process. This is why it is one of the analytical parameters taken into account when defining the categories of olive oil.

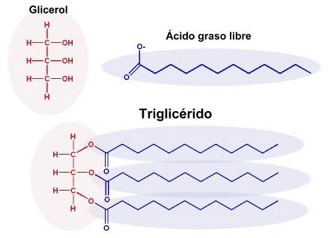

Olive oil is mainly composed of triglycerides, which are made up of a glycerol molecule linked to three fatty acids:

The breaking of the bonds between the glycerol and the fatty acids occurs as a result of the hydrolysis or lipolytic decomposition of some triglycerides (enzymatic hydrolysis, chemical treatment, or bacterial action). This may be caused by pests affecting the olives, blows to the fruit during transport or too long storage from harvesting to extraction, leading to fermentation of the fruit.

The degrees of acidity express the grams of free oleic acid per 100 g of oil. So the acidity of a completely healthy olive at the time of harvesting is 0º.

It is important not to confuse the acidity of virgin and extra virgin olive oil with that of olive oil (mixture of refined and virgin), as the latter has undergone a chemical process in the refinery and the acidity can be corrected. Therefore, in this category it does not serve as a quality parameter.

In conclusion, acidity is an objective parameter of the quality of ‘EVOO’ and at Artajo we take such good care in the production of our liquid gold that we always obtain values of less than 0.2º in all our production.

EVOO does not have an expiry date, as what appears on the label is the ‘best before date’. This is because if it is consumed after the date marked on the label, it does not pose any risk to the consumer.

What the best-before date tells us is the date after which the oil may have lost some of its properties, both from an organoleptic point of view (rancidity, loss of fresh aromas, etc.) and from a health point of view (loss of vitamins, antioxidants, etc.), although it does not pose a microbiological risk.

The legislation on the labelling of extra virgin olive oil gives the producer and/or bottler the criterion of marking the best-before date from the date of bottling (between 18 and 24 months) and not from the date of harvesting. Although the harvest date of an oil is not compulsory, it is important information for the consumer to know, as it indicates the freshness of the product.

Extra virgin olive oil is an ‘olive juice’, so it should ideally be consumed in the year in which it is made. It is during this year after harvesting that most of the antioxidants and vitamins are present, as well as maintaining its freshness and aroma.

Harvesting takes place during the months of October and November in Artajo, and from that date onwards we begin to market the new harvest.

Storage in the final container should be at room temperature at home, from 18 to 22ºC, always protected from light and with the container closed to avoid oxidation.

The variety in an extra virgin olive oil is something that differentiates it and each one of them has different aromatic tones and flavour intensities. If you like bitter oils with a certain spiciness: Koroneiki, Arróniz or Coupage are the ones that will undoubtedly go best with you. If you like sweet oils that are pleasant to the palate: Arbequina, Arbosana or Manzanilla are perfect. Depending on their intended use: Arbequina: Vegetables and preparation of sauces (mayonnaise, aioli, etc.) Arbosana: Citrus fruits and confectionery Arróniz: Vegetables and game stews. Coupage: Warm salads, mushroom carpaccios and pomegranate. Koroneiki: Citrus fruits, endive salads and blue fish, such as red tuna. Manzanilla Cacereña: White fish, chocolate and asparagus.

Extra virgin olive oil tasting here.

Absolutely yes. And you can achieve better results than with other vegetable fats.

Contact us at info@artajo.es to buy Artajo in physical shops. You can also find us in our online shop and at the mill/press itself (Fontellas, Navarra), where we will be delighted to help you.

You can consult here.

Yes, we look forward to welcoming you. We usually make visits on Saturday mornings from September to June, subject to prior booking. For other days, please consult us. You can find out more here.